Density of Maple Syrup

One of the most misunderstood aspects of the maple industry by consumers is the density of maple syrup. After clearing up lingering confusion about the grades of maple syrup, it isn’t unusual to launch into an in-depth conversation about density and the many misconceptions held by the public at large. Flavor and grade of syrup carries a lot of weight but completing density corrections are arguably some of the most important facets of syrup production.

What is Density?

Simply put, density is how much mass can be crammed together to take up a given space. If you had 2 bags of the same size and one bag was heavier than the other, the heavier bag is denser. We could go through the scientific steps to figure out the density or just take the word of Archimedes. Eureka!! What Archimedes learned about the density of the king's gold crown is also applied to our liquid gold.

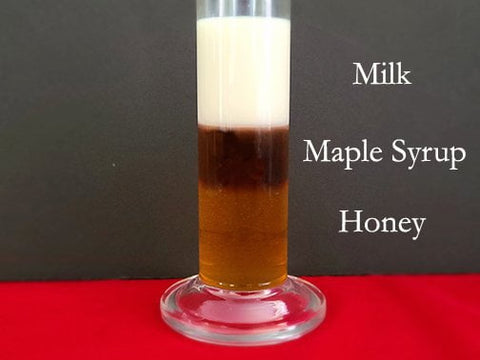

So with that said, maple syrup has a density of 1.37 grams per millilitre, heavier than milk, but not as dense as honey.

If you have kids and want to do a fun density experiment check out this video on Youtube.

Checking the Density of Maple Syrup

When maple syrup is made, the idea is for the sugar maker to draw the syrup from the evaporator at the correct density. When the temperature of the syrup reaches 7 degrees above the boiling point of water (212 degrees F), it has reached the correct thickness. We, and other producers in our industry will often tweak the temperature a few degrees in either direction to get the proper Reading. A calibrated hydrometer is also used to confirm that the maple syrup is at the legal standard, we’ll talk more about this aspect later on in this blog.

Density checks are not only performed at the point of initial production. At the Carman Brook Farm, we store the syrup made during the production season in barrels with the intent to be bottled throughout the year. When the time arrives for canning, we pump a barrel into our canning unit and reheat that syrup to about 140 degrees Fahrenheit. To ensure that the temperature is even, we spend several minutes stirring the maple syrup. At this point we perform our second density check.

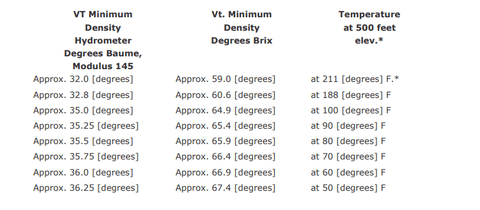

Using a stainless-steel cup and hydrometer, a sample of syrup is withdrawn and tested. Since the syrup is not at the high temperature that was necessary to produce it earlier in the spring, we use a sliding chart that accounts for the change in temperature. The chart adjusts what the brix should be, when the syrup is at a specific temperature.

Official Vermont Regulations of Maple Syrup Density

The Vermont Maple Regulations include a strict standard for maple syrup density. In section 8 of the state regulations, the following paragraph defines the state mandate as a minimum standard, encompassing all grades of syrup:

"All grades of packaged maple syrup shall have a minimum density matching its temperature, as indicated on the following chart, which is equivalent to 36 degrees Baume Modulus 145 or 66.9 degrees Brix at 60 degrees Fahrenheit on instruments calibrated at 60 degrees Fahrenheit or other equivalent measurement of density, as determined by the Secretary of Agriculture.”

In discussion with customers, a misconception is that the darker the syrup, the greater the density. Now that we have all read the state regulations, we can see that this is in fact, not the case. I think that the misconception started because the flavor of darker syrup sticks to your taste buds a little longer, giving a thicker impression.

In Conclusion

For every barrel of syrup, and then again when the canning process begins, we keep production records that log details about the production of the syrup, our personal impressions of taste, and the logging of density. I've summed it all up in about 500 words in this post, but it’s actually a lengthy and tedious process. We take a density reading of our syrup twice, and if another person is present, they do as well with a comparison of notes as the final step. A ton of patience is required to get this stuff right, but our opinion is that the details are what allows our maple syrup and Vermont maple syrup in general, to shine through as the best in the industry.

The link to Vermont Maple Regulations is broken. I found https://agriculture.vermont.gov/sites/agriculture/files/documents/CP/Maple%20Products%20Regulations.pdf and https://agriculture.vermont.gov/food-safety/maple-products

Very helpful article. The density of maple syrup is very well explained.

…. good science.

Leave a comment